December 6, 2022 -- University of Bristol researchers have developed a highly efficient iterative strategy for the synthesis of complex molecules in the laboratory with pharmaceutical applications, including the manufacture of antibiotics and antifungal medicines.

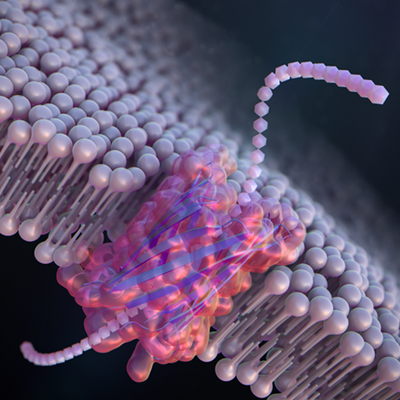

The research, details of which were published November 24 in the journal Nature Chemistry, is focused on polyketides, a class of natural products that are found in bacteria, sea sponges, sediments, and other places. Around one-fifth of all pharmaceuticals are derived from the complex molecules, reflecting their medicinal properties, but they are often found in very small quantities in nature and have long synthesis processes in the lab.

"Due to their highly specific and potent biological activity as well as their structural complexity, polyketide natural products have been attractive targets in chemical synthesis research for over 50 years. Through a different strategy to what others have done before, we have succeeded in developing a step change in efficiency to this important class of molecules," Varinder Aggarwal, PhD, the University of Bristol professor of synthetic chemistry who directed the research, said in a December 5 statement.

Seeking to improve the synthesis of polyketides, University of Bristol researchers tried to create a new process for making bahamaolide A, a polyketide natural product with potent antifungal activity. The molecule originates from bacteria cultured from a marine sediment in the Bahamas and is typically synthesized in a lab process with more than 20 steps.

The new process features an improved way to combine the building blocks for the molecule that reduces the synthesis to 14 steps. The project leveraged the fact that polyketide natural products often contain common repeat motifs, such as propionate, acetate, and deoxypropionate, and can therefore be synthesized by iterative processes. Lead author Sheenagh Aiken, a PhD student at the University of Bristol's School of Chemistry where the work was completed, described how she teamed with collaborators to create a better synthesis process.

"The technique mimics nature by coupling together building blocks and using catalysts to add and modify functional groups in a process like an assembly line," Aiken said. "This highly controlled and predictable approach has potential for making the manufacture of sophisticated molecules more efficient."

Aiken and her colleagues selected bahamaolide A for the synthesis project because it is one of the hardest polyketides to work with and manipulate. Having devised a way to accelerate the production of bahamaolide A, the researchers see opportunities to apply the technique to other molecules and extend the impact of their work.

The team showed the versatility of the approach, which entails iterative synthesis of 1,3-polyboronic esters with high stereocontrol, in various stereospecific transformations. The work led to polyalkenes, -alkynes, -ketones, and -aromatics with full stereocontrol.

Copyright © 2022 scienceboard.net