March 2, 2021 -- For the first time, scientists have successfully produced sugar-based biologic molecules utilizing bacteria, without the need for animal products. The paper, published in Nature Communications on March 2, describes the production of a common designer polysaccharide, chondroitin sulfate (CS).

Sulfated glycosaminoglycans (GAGs) are linear polysaccharides consisting of repeating disaccharide units composed of N-acetylhexosamine and uronic acid. They are ubiquitously distributed on the cell surface and in the extracellular matrix. GAGs play a role in a variety of cellular functions including cell to cell and cell to matrix adhesion, cell proliferation, cell division, morphogenesis, and the regulation of signaling molecules.

Two of the most used GAGs are heparin and CS. Heparin is the main anticoagulant used in modern medicine. On the other hand, CS is the most abundant GAG found in the body and is an important component of joint tissues. It is commonly used for the treatment of osteoarthritis.

Specific interactions of GAG functional groups with biomolecules produce anticancer and antidiabetic properties that have increased the demand for pure, chemically defined GAGs.

Because these molecules are exclusively present in animals, all commercially available GAGs are produced by extraction from animal tissues, primarily from bovine trachea and porcine intestinal mucosa.

However, difficulties in downstream purification, complex and expensive quality control steps, risk of cross-viral contaminations, nonsustainability, as well as heterogeneity in GAGs from animal tissues and cultural trends against animal-sourced products are driving innovation in GAG manufacturing toward sustainable, microbial-based processes.

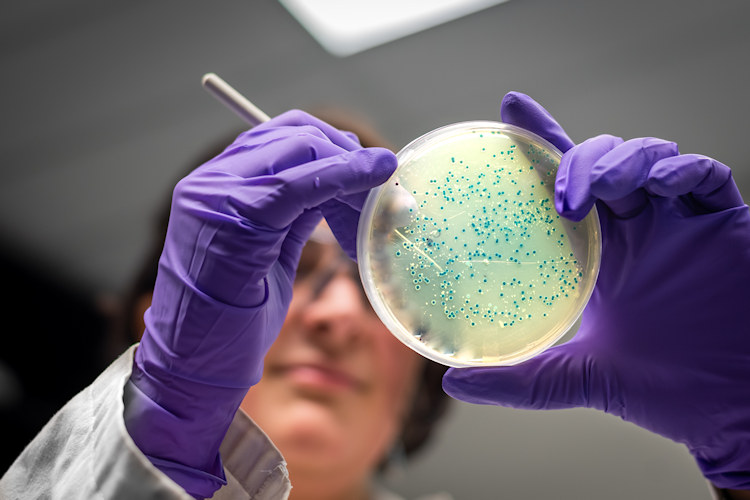

While chemical synthesis methods for the production of GAGs, specifically CS, have traditionally been tedious and difficult to scale, a group of researchers from Rensselaer Polytechnic Institute Center for Biotechnology and Interdisciplinary Studies (CBIS) sought to modify Escherichia coli to support the biosynthesis of CS.

"It's a challenge to engineer E. coli to produce these molecules, and we had to make many changes and balance those changes so that the bacteria will grow well," said Mattheos Koffas, PhD, lead researcher and a professor of chemical and biological engineering at Rensselaer Polytechnic Institute, in a statement. "But this work shows that it is possible to produce these polysaccharides using E. coli in animal-free fashion, and the procedure can be extended to produce other sulfated glycosaminoglycans."

Biosynthesis of CS in E. coli requires three factors: unsulfated chondroitin precursor, the sulfate donor 3′-phosphoadenosine-5′-phosphosulfate (PAPS), and chondroitin sulfotransferase. Of the 11 metabolic steps to synthesize chondroitin, nine are already present in commonly used E. coli strains. Importantly, enzymes for the two remaining steps (uridine 5'-diphospho (UDP)-N-acetylglucosamine-/UDP-glucosamine-4-epimerase and chondroitin synthase) have been identified in other bacteria. Because of this, the researchers selected E. coli K4 as a starting point for the engineered bacteria.

Building the one-step biosynthesis bacteria

To begin, the team determined that sulfation of chondroitin to CS requires PAPS, the availability of which is a limiting factor for CS production. As such, they engineered E. coli through deletion of 3'-phospho-adenylylsulfate reductase (CysH), which catalyzes the reduction of PAPS to sulfite and phosphatidate phosphatase. This led to ample supply of the sulfur donor molecule and a high intracellular CS sulfation level.

Next, a working sulfotransferase enzyme was introduced into the bacteria. The team focused on the introduction of chondroitin-4-O-sulfotransferase that results in the production of the 4-O-sulfated chondroitin 4-sulfate (CS-A). The authors noted that different chondroitin sulfotransferases give rise to different forms of CS. This step posed a particularly difficult challenge for the scientists.

"The sulfotransferases are made by much more complex cells," Koffas said. "When you take them out of a complex eukaryotic cell and put them into E. coli, they're not functional at all. You basically get nothing. So, we had to do quite a bit of protein engineering to make it work."

Using a computational approach, the researchers identified three mutant enzymes that demonstrated enhanced in vitro sulfotransferase activity. One efficient mutant was selected for integration into the engineered E. coli strain, which further improved in vivo sulfation.

The authors discussed additional factors, such as optimal incubation temperatures to maximize in vivo sulfation, improved engineering of sulfotransferases for better in vivo activity, and strain designs that limit CS export that could improve the overall production of microbial-based CS. The authors also noted that unlike the animal-derived CS, the experimental microbial product does not contain any impurities, such as chondroitin 6-sulfate (CS-C).

"The ability to endow a simple bacterium with a biosynthetic pathway only found in animals is critical for synthesis at commercially relevant scales," said author Jonathan Dordick, PhD, professor of chemical and biological engineering at Rensselaer. "Just as important is that the complex medicinal product that we produced in E. coli is structurally the same as that used as the dietary supplement."

While the relative yields of the microbial product are small -- on the order of micrograms per liter – they thrive under ordinary lab conditions, offering a robust proof of concept, according to the authors.

"This work is a milestone in engineering and manufacturing of biologics and it opens new avenues in several fields such as therapeutics and regenerative medicine that need a substantial supply of specific molecules whose production is lost with aging and diseases," said Deepak Vashishth, PhD, director of the CBIS.

Do you have a unique perspective on your research related to bacteriology or genomics? Contact the editor today to learn more.

Copyright © 2021 scienceboard.net