February 4, 2020 -- A first-in-class system that effectively embeds engineered microbes into the solid support of a 3D-printed hydrogel is described in a report published in Nature Communications on February 4. The hydrogel system organizes both individual microbes and groups of microbes for on-demand production of pharmaceuticals.

Microbial production of a range of products from small molecules to complex proteins has been advanced by synthetic biology and the ability to produce molecular microbial populations across multiple organisms, creating synthetic consortia. Bioprocess applications, namely liquid culture systems, rely on large-scale suspension fermentation technologies that are not easily portable, reusable, or suitable for on-demand production.

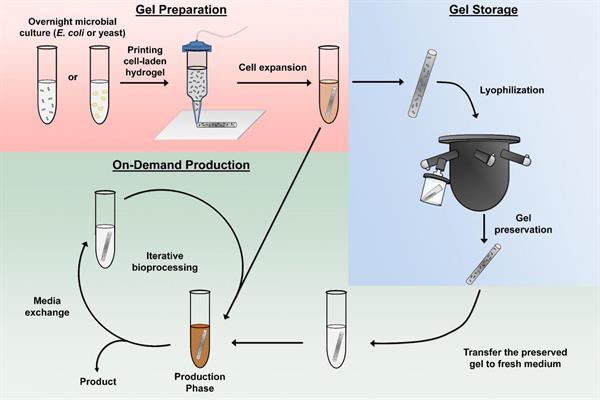

Developed as an alternative to liquid culture, immobilized cell technologies encapsulate microbes within a polymeric matrix, and these materials can be used as 3D-printed living materials. Researchers from the University of Texas at Austin have developed a hydrogel system that compartmentalizes microbes to build spatially segregated microbial consortia.

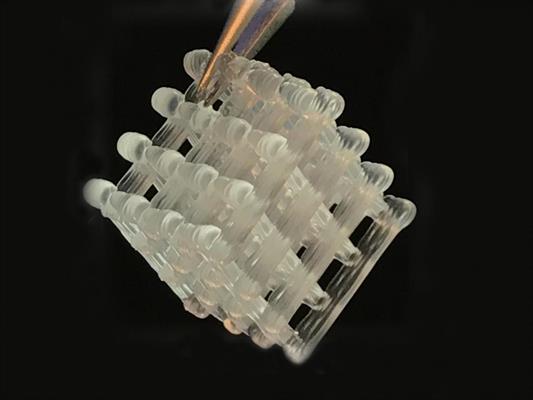

They demonstrate that temperature-responsive, shear-thinning behavior (decreased viscosity under strain) of the hydrogel, F127-bisurethane methacrylate (F127-BUM), allowed the material to be extruded as filaments from a nozzle in 3D printing. After exposure to ultraviolet (UV) light, the material hardens. Molecularly, the resulting polymer network is large enough for molecules and proteins to move through it, but the space is too small for cells to leak out.

The hydrogel system was utilized for the production of four chemical compounds, a peptide antibiotic, and carbohydrate catabolism by using either mono- or cocultures. Fermentation of both bacterial and yeast-laden gels successfully produced value-added biochemicals: 2,3-butanediol, 3,4-dihydroxy-L-phenylalanine (L-DOPA), ethanol, and a peptide antibiotic (colicin V).

Achieving cocultures is challenging in traditional systems, as it requires spatial organization as well as a protective environment for the microbes to thrive noncompetitively. The researchers compartmentalized consortium through simple spatial separation within printed hydrogel constructs in a way that removes growth competition between organisms. The composition of each organism can be controlled by changing the amount of each respective gel extruded. Therefore, the system enables a plug-and-play approach to combining and optimizing chemical production.

"We have taken a completely different angle for fermentation by utilizing hydrogels," said Hal Alper, PhD, a professor at the University of Texas at Austin's Cockrell School of Engineering, in a statement. "Many of the chemicals, fuels, nutraceuticals and pharmaceuticals we use rely on traditional fermentation technology. Our technology addresses a strong limitation in the fields of synthetic biology and bioprocessing, namely the ability to provide a means for both on-demand and repeated-use production of chemicals and antibiotics from both mono- and cocultures."

The team also found that by lyophilizing, or freeze-drying, the hydrogel system, it can effectively preserve the fermentation capacity. They demonstrated the robustness of the system after a yearlong process in which, after rehydration and incubation in fresh medium, the cells will convert into product just as effectively as before preservation.

Medicines such as antibiotics have a certain shelf life and require particular storage conditions. The portability of the hydrogel system makes it especially useful in remote places, without access to refrigeration to store medications. It would also be a small and compact way to maintain access to several medications and other essential chemicals when there is no access to a pharmacy or a store. Although not quite there yet, the possibilities are promising.

"This technology can be applied to a wide range of products and cell types. We see engineers and scientists being able to plug and play with different consortia of cells to produce diverse products that are needed for a specific scenario," Alper said. "That's part of what makes this technology so exciting."

Copyright © 2020 scienceboard.net